Airport Ground Support

WH Kemp is flying high! WH Kemp: a reliable supplier of Cable Harnesses and Control Panels for airport ground support

WH Kemp is flying high! WH Kemp: a reliable supplier of Cable Harnesses and Control Panels for airport ground support

WH Kemp’s experience in the aerospace sector spans several decades Customers benefit from our specialist expertise and reputation as a

‘Trains and Boats and Planes’ Music: Burt Bacharach. Song: Dionne Warwick. Cable Assemblies: WH Kemp! Arguably the most tenuous link

WH Kemp, mixing it with the tough guys! JCB, Red Rhino, Palfinger/TH White and Thwaites. Some of the biggest names

The name’s Kemp. WH Kemp. Licensed to manufacture Defence Cable Assemblies and Control Panels Given the recent (long-awaited) release of

Partnering with start-ups and advanced manufacturers in the Electric Vehicle sector We have been working in partnership with those working

WH Kemp’s very own ‘Electric Light Orchestra’ of Cable Assembly Experts WH Kemp has been providing Wiring Looms, Sub-Assemblies and

WH Kemp is proud to have played a small part in the fight to beat Covid-19 The world has a

Decades of proven Cable Harness Automotive expertise continues to drive customers to our door Throughout WH Kemp’s 50+ year history,

Fire Detection and Equipment for Hazardous Environments Customers working with the design and manufacture of equipment for fire detection and

Customers demanding quality, delivery on time and price competitive cable sub-assembly builds that fit perfectly into their generator products need

WH Kemp have been building cable looms and control panels for the HVAC sector for over two decades. Major customers

WH Kemp’s skills in building complex and reliable Cable Harnesses has only recently been discovered by those working in the

Supporting the design and manufacture Cable Harnesses for the Nuclear Sector for over 18 years. WH Kemp has been manufacturing

Building Cable Harnesses for Scientific Instruments can be especially challenging and the WH Kemp team meet the challenge every time.

WH Kemp supports several Micro Business and SMEs through trialling and building Wiring Looms and Cable Assemblies for companies in

WH Kemp has been partnering high-tech companies working in the green energy sector for over 10 years. Companies involved with

WH Kemp’s business is grounded in supplying Cable Assemblies and was established in 1967, primarily to manufacture sub-assemblies for what

High-tech machine manufacturers elect to choose WH Kemp. Understandably, a prerequisite of these fast-moving customers is absolute trust in our

WH Kemp has been involved in rolling stock projects, rail signals, rail safety equipment and passenger gate and ticketing systems

WH Kemp prides itself in being a valuable supply chain partner to businesses manufacturing mission critical equipment. This is especially

WH Kemp is the UKs longest serving specialist Cable Harness manufacture, having been continuously trading since 1967. The company is

WH Kemp, building Control Boxes and Cable Assemblies for the mobile telecom sector and aiding the rollout of the 5G

Our facilities, processes, people and governance combined with our sector leading results for quality, delivery and value, make us the ideal partner for world class manufacturers.

We work for demanding businesses who operate in various industrial sectors. Since 1967 we’ve worked primarily with multi-national businesses who manufacture mission critical machines and instruments.

We welcome representatives from these corporations to our factory. Following on from these visits, all the representatives recommend working with us.

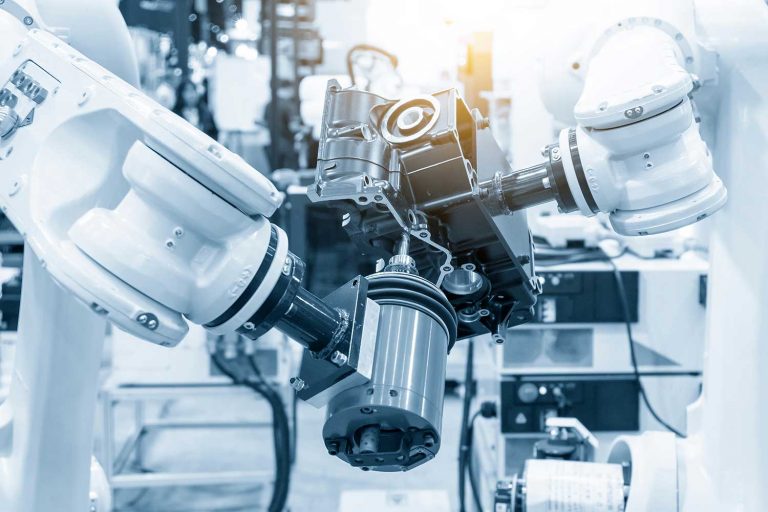

In recent years we have started working with smaller manufacturers and high-tech companies, including robotics, motor racing and those involved with new technologies.

If you are looking to partner with a sector leading Cable Harness and Control Box manufacturer, please visit us and meet our team. You will not be disappointed.

Please talk to one of our experienced team on 01373 823322 or email sales@whkemp.co.uk

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Prior to acquiring WH Kemp in 2012, John’s business career spanned 30 years in the City of London and in Continental Europe; specifically, Switzerland and Hungary. He successfully directed business units within a number of multinationals, in the consumer, retail and engineering sectors. Amongst the companies where John has worked are Wilkinson Sword, Swedish Match, Pharmacia and Tesco. He has also held the position of MD at various manufacturing SMEs. This wealth of business experience, in tandem with John’s personal and open management style, has proved invaluable at WH Kemp in cementing excellent customer and staff relationships. John also holds an MBA from CASS Business School.